7Solutions India Top Steel Detailing Company in Worlds – Top Steel Detailing Services Provider in World

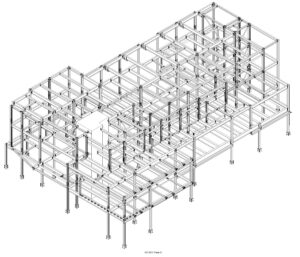

7Solutions India provides an advanced approach to steel detailing services that can handle a wide range of structural steel detailing projects for both residential and commercial construction. Our team of experienced steel detailers uses the latest software and technology to create accurate and detailed drawings for various steel structures.

We understand that each project has unique requirements, and we work closely with clients to understand their needs and provide customized solutions that meet their specific requirements. Our team has extensive experience in steel detailing services, and we are equipped to handle projects of any size and complexity.

Whether it’s preparing steel shop drawings, steel fabrication drawings, steel erection drawings, or providing miscellaneous steel detailing services, we ensure that our clients receive high-quality and accurate drawings that meet their project requirements.

At 7Solutions India, we pride ourselves on delivering high-quality services within time and budget constraints. Our team works closely with clients to ensure that they are informed throughout the project, and we adhere to the highest standards of quality, accuracy, and professionalism.

Once the plan of action is established, a structural steel detailing team will create a set of drawings and plans that detail the intricate components needed to construct your project. This includes all the specifics such as size, shape, type of steel, welding requirements, etc. Once the drawings and plans are complete, they are then sent to the fabrication shop for fabrication and assembly. This process ensures that all components are made to meet the exact specifications of the project. The structural steel detailing process is often followed by structural steel erection on site.

Our structural steel detailing professionals then formulate a detailed cost estimate based on this plan, which is later implemented by our expertly trained construction staff. Our structural steel detailing professionals create a detailed plan based on their analysis and then formulate a cost estimate. Our expertly trained construction staff then implement this plan.

Our structural steel detailing professionals create detailed plans and drawings for each project that includes the sizes, shapes and types of steel components that are required. They then use software to calculate the forces, loads and other characteristics of the steel components to ensure that they are strong enough to handle the project’s purpose. The detailed plans also include exact measurements, welding instructions and other instructions necessary for the fabrication and installation of the steel components.

SOME OF OUR MOSTLY USED STRUCTURAL STEEL DETAILING SERVICES:

Steel detailing services

Shop drawings services

Working drawings services

Grating detailing services

Carport steel detailing services

Canopy steel detailing services

Fabrication shop drawings

Bar joists drawings

Erection drawings services

Anchor bolt plan drawings

Steel member’s services

Misce. steel detailing services

Steel stair case detailing services

Stair handrail detailing services

Fence detailing services

Metal detailing services

Windows detailing services

Door detailing services

OUR STEEL DETAILER’S HAVING EXPERTISE IN:

Steel Platform Shop Drawings

Steel Bridge Shop Drawings

Steel Shed Shop Drawings

Steel Rack Shop Drawings

Steel Column Shop Drawings

Steel Beam Shop Drawings

Steel Lintel Shop Drawings

Steel Joists Shop Drawings

Steel Deck Shop Drawings

Steel Frame Shop Drawings

Steel Stair Shop Drawings

Anchor Bolt Plans Shop Drawings

Steel Conveyors Shop Drawings

Email us: info@7solutionsindia.com or CLICK HERE to fill up small quick contact form, Ask our experts steel detailers about your structural steel detailing projects. Our structural steel detailers will assist you within 1 business day.

Contact us today to learn more about how we can assist with your structural steel detailing needs for residential and commercial construction projects.